Boost Production Efficiency with an Industrial Laser Cutter Machine and Engraver

CODE

Boosting production without losing quality is a real concern for many Australian workshops. Deadlines are tighter, customers expect more detail, and competition keeps prices under pressure. This is where an industrial laser cutter machine paired with a capable laser cutter engraver can seriously change how work gets done. Modern desktop machines are no longer limited to hobby use. With the right setup, they support real production, repeat jobs, and professional results. This guide focuses on practical projects, production ideas, and everyday efficiency using a machine that fits Australian workshops without overcomplication.

Thinking About Production Before Cutting

Good efficiency starts long before pressing the start button. Workshops that plan their jobs properly get far more value from an industrial laser cutter machine. Design files should be reusable, easy to adjust, and built for batch work. A laser cutter engraver allows fast test runs, which helps catch issues early instead of wasting material halfway through a job.

Material Selection That Makes Sense

Different materials react differently to laser power and speed. Timber engraves differently from acrylic, and coated metals behave differently again. Keeping a simple record of settings helps operators stay consistent. Over time, this builds confidence and speeds up setup across repeat orders.

Project Ideas That Are Easy to Sell

Choosing the right products matters just as much as choosing the right machine. An industrial laser cutter machine opens doors to items that are profitable and scalable. A laser cutter engraver adds personalisation without slowing production, which is exactly what many customers want.

Popular project ideas include:

- Custom business signage for shops and offices

- Branded packaging inserts for online sellers

- Decorative wall panels and room dividers

- Award plaques and corporate trophies

- Product labels and display stands

These projects suit both short runs and repeat orders, which helps stabilise cash flow.

Why the Monport Reno65 Pro Vision Stands Out

Not every machine is built for consistent daily use. The Monport Reno65 Pro Vision is designed to bring cabinet-level power into a desktop format. As an industrial laser cutter machine, it offers serious cutting ability while remaining compact enough for smaller workshops. As a laser cutter engraver, it focuses on precision, ease of use, and reliable performance.

Key Specifications That Support Real Work

The Reno65 Pro Vision runs at 65W and reaches engraving speeds of up to 800 mm/s. Its working area measures 24 x 16 inches, giving enough room for larger designs or multiple items at once. The adjustable Z-axis moves up to 4 inches, allowing thicker materials and creative setups. With a laser service life estimated at 4500 hours, it is built for long-term use.

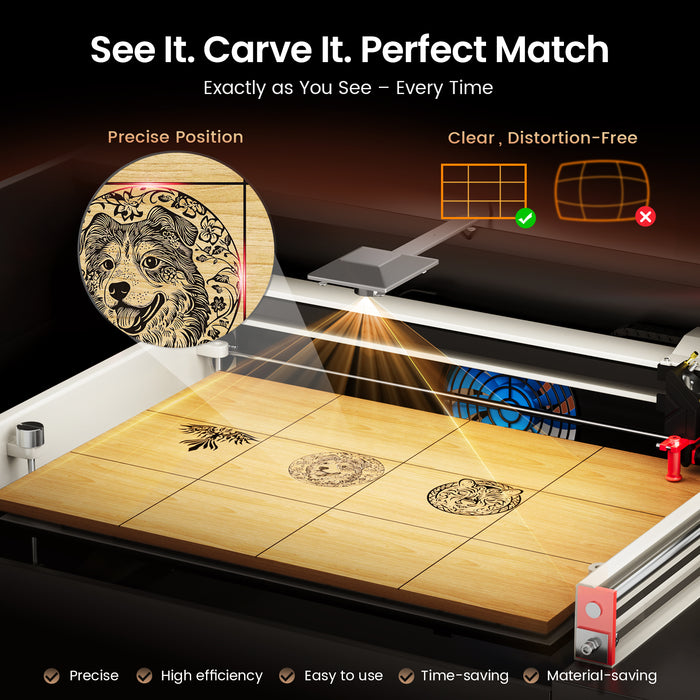

Camera-Based Alignment Saves Time

The built-in 8MP HD camera makes positioning designs faster and more accurate. Visual alignment reduces setup errors and speeds up workflow, especially for detailed engraving or multi-item layouts. For busy workshops, this feature alone can save hours over a week.

Improving Daily Workflow

Efficiency is not just about speed. It is about smooth operation from start to finish. A laser cutter engraver with stable motion control produces consistent results across long runs. An industrial laser cutter machine with a solid frame and reliable cooling system handles extended use without overheating.

Clean Cuts and Clear Engraving

The adjustable air assist system clears smoke and debris from the cutting path. This results in cleaner edges and sharper engraving details. Combined with a honeycomb or blade workbed, materials stay flat and well supported throughout the job.

Power and Precision in a Desktop Size

The Reno65 Pro Vision packs serious capability into a compact footprint. It can cut acrylic up to 20 mm thick while still delivering fine engraving detail. This balance of power and control makes it suitable for both bold signage and delicate artwork.

Compact Yet Flexible Design

Despite its desktop size, the machine offers an expansive work area and a hidden front pass-through for longer materials. Support for rotary engraving expands product options to bottles, cups, and cylindrical items. This flexibility helps workshops diversify without buying extra machines.

Safety and Confidence on the Shop Floor

Safety features are not optional in a production environment. The Reno65 Pro Vision includes certifications such as CE and FDA, along with a stable enclosure design. Reliable cooling through an external water pump keeps operating temperatures steady. A safer machine leads to fewer interruptions and more consistent output.

Software Compatibility That Reduces Friction

The machine supports popular software like LightBurn, Autolaser, and TopwisdomLaser. This means designers and operators can work in familiar environments. Compatibility across Windows, macOS, Linux, and even mobile platforms allows flexible file handling in shared workspaces.

Multiple Data Connections

USB, WiFi, and U-Disk support give teams several ways to send files to the machine. This flexibility is useful when multiple operators share the same equipment or when quick file changes are needed during production.

Scaling From Small Jobs to Larger Orders

Many Australian workshops start with small custom projects and grow into repeat production. An industrial laser cutter machine supports this growth by maintaining accuracy during long sessions. A laser cutter engraver ensures fine details stay sharp even when running at higher speeds.

Expanding Product Ranges

With rotary support and adjustable bed height, workshops can take on new product types without changing equipment. This makes it easier to respond to customer demand and seasonal trends.

Maintenance That Fits Real Schedules

No one wants a machine that needs constant attention. The Reno65 Pro Vision is designed for straightforward maintenance. Stable motion components, efficient cooling, and quality optics reduce wear. Routine cleaning and basic checks are usually enough to keep it running smoothly.

Managing Costs and Long-Term Value

Investing in an industrial laser cutter machine is a business decision, not just a purchase. Bringing cutting and engraving in-house reduces outsourcing costs and shortens turnaround times. A laser cutter engraver adds personalisation that increases product value without adding labour.

Workshops that plan projects carefully often see faster return on investment through repeat orders and higher margins.

Practical Tips for Better Results

- Organise design files clearly

- Record material settings for future reference

- Train operators on basic troubleshooting

- Schedule cleaning during slower periods

These habits may seem small, but they make daily work easier and more consistent.

FAQs

What types of workshops benefit most from this type of machine

Sign makers, product designers, packaging suppliers, and small manufacturers all benefit from faster turnaround and reliable quality.

Is the Reno65 Pro Vision suitable for beginners

Yes. Features like magnetic assisted focus and camera alignment make it easier for new users to get accurate results quickly.

How much space is needed for installation

The desktop format fits well in most workshops. Allow extra room for ventilation and material handling.

Can it handle both cutting and engraving in one job

Yes. Switching between cutting and engraving within the same project is straightforward and efficient.

How often does maintenance need to be done

Basic cleaning should be done regularly, with deeper checks depending on usage levels.

Key Takeaways

- Industrial laser cutting improves speed and consistency

- Engraving adds value without slowing workflow

- Desktop machines can now handle serious production

- Planning and setup matter as much as machine power

- Blog code for exclusive discounts: AUBLOG888

Conclusion

For workshops looking to improve output, reduce waste, and expand their project range, an industrial laser cutter machine offers a strong advantage. When combined with a capable laser cutter engraver like the Monport Reno65 Pro Vision, production becomes faster, more accurate, and easier to manage. Its balance of power, precision, and user-friendly design makes it a practical choice for Australian businesses ready to grow.

GA 60W

GA 60W

GA 100W

GA 100W

GQ 30W

GQ 30W

GQ 50W

GQ 50W

GPro 60W

GPro 60W

GPro 100W

GPro 100W

Reno 65W

Reno 65W

Reno 65W Pro

Reno 65W Pro

Reno 45W Pro Vision

Reno 45W Pro Vision

Reno 45W Pro

Reno 45W Pro

Reno 45W

Reno 45W

Leave a comment